The Future of Construction Painting: Top Trends to Watch in 2025

I’ve been in the construction painting industry long enough to remember when the only choices we had were oil-based or latex paint, and the fanciest tool on the jobsite was a sprayer that jammed half the time. Fast forward to 2025, and painting in construction has become almost unrecognizable. From smart paints that clean themselves to robotic sprayers covering entire walls in minutes, the trade is evolving fast.

If you’re a builder, contractor, or fellow painter, staying ahead of these changes isn’t optional anymore—it’s essential. Clients are asking for greener solutions, projects are moving faster, and competition is tougher than ever. In this article, I’ll walk you through the top construction painting trends shaping 2025, along with some practical insights from the field.

The future of construction painting in 2025 is shaped by several cutting-edge trends focused on efficiency, sustainability, durability, and advanced technology. Key trends include the rise of fast-drying paints to speed up project timelines, eco-friendly and low-VOC paints that reduce environmental impact, self-healing and graphene-infused coatings for enhanced durability, and the use of augmented reality (AR) tools for color visualization aiding decision-making on-site. Additionally, specialty aerospace and anti-microbial coatings are becoming more common in construction to meet demands for performance and health safety.

Smarter, Greener Paints

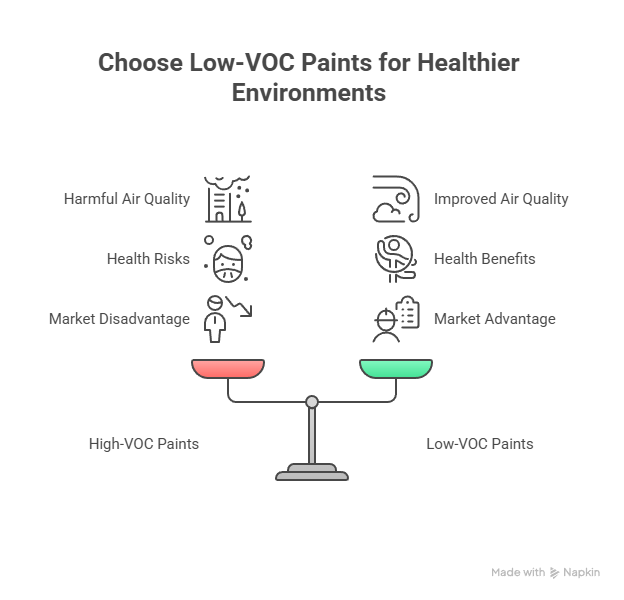

The first big trend we can’t ignore is eco-friendly construction painting. Regulations around the world are tightening, and both commercial and residential clients are asking for healthier, sustainable options.

Low-VOC and Zero-VOC Paints

Back in the day, we all put up with that strong “new paint smell.” Today, that smell means high VOCs (volatile organic compounds), which are harmful to indoor air quality. By 2025, low-VOC and zero-VOC paints have become the standard, especially in schools, hospitals, and modern office buildings.

As painters, we benefit too—it’s easier on our lungs and safer on long projects. If you’re a contractor, specifying low-VOC paints in your bids can give you an edge with environmentally conscious clients.

Smart Paint Technology

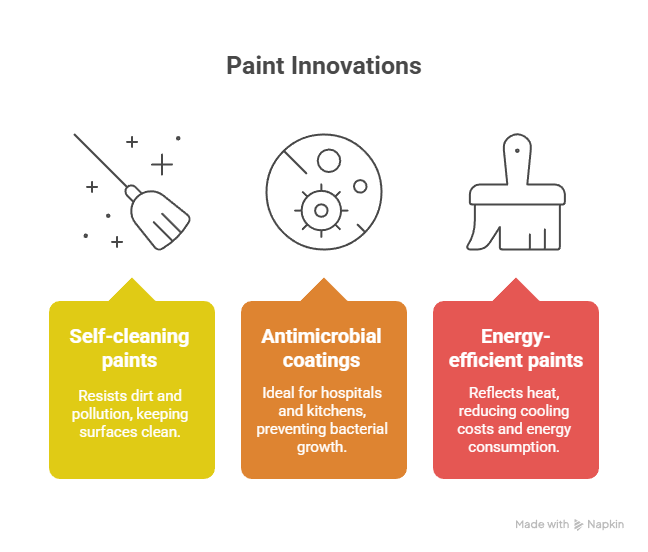

We’re also seeing smart coatings making their way into construction sites:

- Self-cleaning paints that resist dirt and pollution.

- Antimicrobial coatings for hospitals and kitchens.

- Energy-efficient paints that reflect heat to reduce cooling costs.

These options might cost more upfront, but I tell clients it’s like buying a roof that lasts twice as long—smart paints save money on maintenance and energy in the long run.

Automation and Spray Technology

I’ve rolled more walls than I can count, but in 2025, robotic sprayers and advanced spray technology are becoming standard, especially on large-scale construction projects.

Robotic Sprayers

These machines can paint entire high-rise walls with consistent coverage, cutting labor hours dramatically. For repetitive, large surfaces like warehouses or commercial interiors, they’re a game changer.

Advanced Spray Systems

Even for smaller contractors, spray technology has come a long way. Modern airless sprayers are faster, less wasteful, and easier to control, giving a smoother finish than traditional brushes and rollers. For us painters, that means higher productivity and fewer callbacks.

Digital Tools for Painters

The construction industry has gone digital, and painting is no exception.

Color-Matching and Visualization Apps

Clients these days don’t want to “imagine” how a color will look—they want to see it. Apps now let us scan a wall, upload a photo, and show the exact finish in real time. That makes the client decision-making process smoother and reduces costly color-change requests mid-project.

Project Management Software

On big jobs, painters are using apps to track paint usage, manage crews, and stay aligned with general contractors. This reduces delays and keeps projects within budget. In 2025, tech-savvy painters will always have the edge.

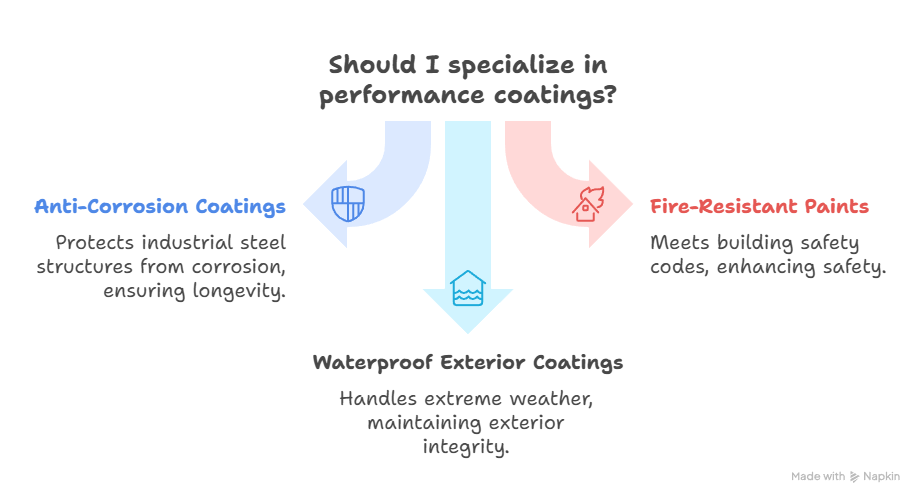

Durability and Performance-Focused Coatings

Not all paints are created equal, and in 2025, more clients are investing in performance coatings that last longer and do more.

- Anti-corrosion coatings for industrial steel structures.

- Fire-resistant paints to meet building safety codes.

- Waterproof exterior coatings that can handle extreme weather.

Sure, these paints cost more per gallon, but they save money over the life of a building. For painters, knowing how to apply these specialized coatings can make you a sought-after professional.

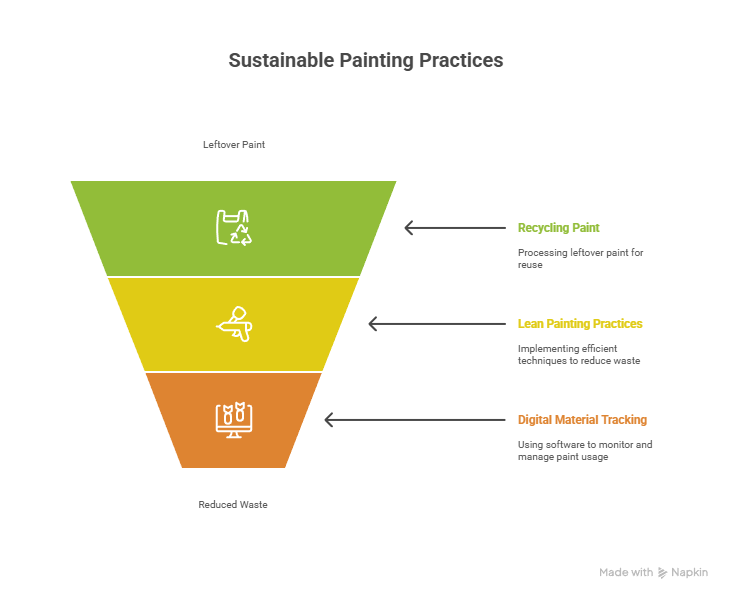

Sustainability and Waste Reduction

Green building isn’t just about what’s in the paint—it’s also about how we use it.

- Recycling leftover paint instead of sending it to landfills.

- Using lean painting practices like better masking and controlled spraying to reduce waste.

- Tracking material use digitally to avoid over-ordering.

Many commercial bids now ask contractors to outline their sustainability practices. Painters who can show waste reduction strategies stand out in 2025.

Skilled Workforce & Training

Here’s the truth: the tools and materials are evolving, but so must the painters.

- Learning how to handle advanced coatings requires proper training.

- Spray application is becoming the norm, but not everyone knows how to do it right.

- Safety standards are stricter with new chemicals and technologies.

As someone who’s trained younger painters, I can tell you: investing in skills pays off. The demand for skilled, tech-savvy painters is only growing.

Changing Client Expectations

Clients in 2025 expect more than just a paint job.

- They want eco-friendly solutions.

- They want faster turnaround times without sacrificing quality.

- They expect painters to provide design input, like helping choose finishes and colors that align with branding or home styles.

If you’re in the painting business, offering consultation services along with application sets you apart. It’s not just about covering walls anymore—it’s about delivering value.

FAQs About Construction Painting in 2025

Q: Are smart paints worth the investment?

A: Yes. While they cost more upfront, smart paints like self-cleaning or energy-efficient coatings can save money on maintenance and utility bills over the years.

Q: Will robots replace painters?

A: Not completely. Robots handle repetitive, large-scale jobs, but skilled painters are still needed for detail work, touch-ups, and client communication.

Q: How do I know if I need low-VOC paint?

A: If you’re painting in schools, hospitals, or residential interiors, low-VOC or zero-VOC paints are usually required and always a healthier choice.

Q: What’s the best way for painters to stay competitive in 2025?

A: Keep learning—whether it’s mastering spray equipment, using digital tools, or training in new coating applications.

Final Thoughts

Construction painting in 2025 isn’t just about brushes and rollers—it’s about innovation, sustainability, and skill. As an industry veteran, I can tell you this: the painters who embrace new technology, adopt green practices, and upskill continuously will not just survive—they’ll thrive.

Call to Action

If you’re a contractor or builder looking to stay ahead, start talking to your painting teams about these trends now. And if you’re a painter, don’t wait—invest in new tools, training, and eco-friendly solutions. The future of construction painting is already here, and those who adapt will be the ones leading the industry.

Contact us now!